XENIA® PRESENTS NEW RANGE OF IMPACT MODIFIED THERMOPLASTIC MATERIALS

Xenia Materials introduces the new ST Upgrade: a technology designed to enhance the impact resistance of its fibre reinforced materials.

Fibre-reinforced thermoplastics are well established for their exceptional balance of mechanical strength, stiffness and reduced weight. However, certain applications are subjected to conditions that require performance beyond what standard grades can offer.

ST UPGRADE

SUPER TOUGH UPGRADE

The ST Upgrade delivers a remarkable increase in impact resistance, achieving an average improvement of 60% compared with original formulations and ensuring reliable performance both at room and low temperatures.

Simultaneously, it enhances flexibility and elastic behaviour, with elongation at break increased by an average of 40% compared with non-upgraded formulations.

APPLICATIONS

The ST Upgrade can be applied to applications that demand advanced performance, from aerospace and motorsport, where lightweight and high-stiffness components are essential, to consumer goods requiring structural reliability, such as ski boots, bindings, mountain boots, hockey skates and shoe soles and plates.

The ST Upgrade can be selected and applied across a defined range of Xenia formulations, including:

Thanks to its versatility, the ST Upgrade can be applied to any polymer base and reinforcement processed by Xenia, offering maximum design freedom and delivering tailored solutions for the most demanding applications.

XELIGHT®: LIGHTWEIGHT MATERIALS FOR SUPERIOR PERFOMANCE

What drives the material choice in sports footwear?

When it comes to sports footwear, materials are required to ensure lightness, flexibility, structural support and responsiveness.

These properties are essential to meet the high standards of designers and athletes, enabling footwear to deliver speed, control and reactivity with every movement.

Xenia has developed a range of materials that redefines lightness, without sacrificing mechanical and functional performance.

XELIGHT®

XTREME LIGHTWEIGHT MATERIALS

Based on PEBA, XELIGHT® is Xenia’s range of ultralight thermoplastic composites designed for the sports and athletic footwear industry.

Thanks to their elastic structure and lightness, these materials represent the ideal solution for applications that require agility, responsiveness and freedom of movement.

MATERIALS PROPERTIES

Lightness

Engineered with Xenia’s SuperLight Technology, these materials deliver densities as low as 0.87 g/cm³ without compromising on mechanical strength.

Flexibility

Thanks to their flexibility, XELIGHT® adapt seamlessly to natural movements, delivering both dynamic performance and superior comfort.

Energy Return

Xelight® optimized flexural response with low energy dispersion ensures superior rebound, boosting propulsion and maintaining performance over time.

Impact Resistance

Their impact resistance, even at low temperatures, ensures effective energy absorption and dissipation, as well as increased durability, providing protection and support during activity.

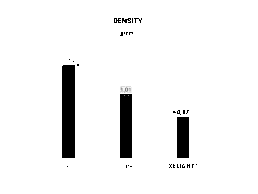

PERFORMANCE COMPARISON

XELIGHT® vs PEBA vs TPU

This range of materials was developed to meet the demands of high-performance footwear, offering mechanical strength and flexibility at an exceptionally low weight. The lower density, compared to PEBA and TPU, opens new possibilities in lightweight shoe design.

*Data for TPU and PEBA are based on publicly available values

APPLICATIONS

CARBON FIBER-REINFORCED FILAMENTS FOR 3D PRINTING: PA11 vs PA12

In the 3D printing industry, producing functional components that match the performance of traditional manufacturing methods requires materials that offer an optimal balance of low weight and high mechanical strength.

Among these, carbon fiber-reinforced PA11 stands out as a bio-based solution that combines mechanical properties, chemical resistance and sustainability.

On the other hand, carbon fiber-reinforced PA12 remains one of the most established solutions for producing high-performance components, especially in sectors such as automotive, aerospace, and precision engineering.

Which one to choose?

XECARB® SL 3DF

Lightened 15% Carbon Fibre Reinforced PA11

Based on the properties of PA11, Xenia has developed XECARB® SL 3DF, a technical filament reinforced with 15% carbon fiber that delivers an exceptional combination of strength and lightness, featuring a density of only 0.99 g/cm³.

Lightness

Structural performance

Impact Resistance

SUPERLIGHT TECHNOLOGY

By integrating proprietary Superlight technology, XECARB® SL 3DF achieves a significantly lower density than conventional filaments, enabling the manufacture of lightweight, strong, and durable parts without sacrificing mechanical performance.

*Data for PA12 + 15% Carbon Fibre is based on publicly available values

SuperLight technology allows for up to a 20% reduction in mass per unit volume, optimizing material usage and enhancing production efficiency compared to standard, non-lightweight filaments.

CARBON FIBRE-REINFORCED PVDF FOR THE CHEMICAL PROCESS INDUSTRY

PVDF is widely used in the chemical industry due to its excellent resistance to corrosive substances and its strong thermal performance.

However, in hazardous operating conditions classified as ATEX, the material may exhibit some limitations

When carbon fibre is integrated into polymer matrices such as PVDF, it acts as a reinforcement that significantly enhances the material’s properties, allowing it to:

PERFORMANCE COMPARISON

MECHANICAL RESISTANCE

The addition of carbon fiber progressively increases the stiffness of the material, enhancing its resistance to deformation under increasing pressure.

Comparison between unfilled PVDF, 10% carbon fibre reinforced PVDF and 20% carbon fibre reinforced PVDF.

ELECTRICAL CONDUCTIVITY

Carbon fibre reinforcement contributes to increase the electrical conductivity, allowing the material to perform antistatic functions in applications where electrical charges dissipation is essential.

Comparison between unfilled PVDF and carbon fibre-reinforced PVDF.

INDUSTRIES AND APPLICATIONS

Thanks to its enhanced properties, carbon fibre-reinforced PVDF proves to be a reliable choice for applications that demand high performance in terms of strength, durability and safety, especially in complex and high-risk environments.

XENIA’S PRODUCTS FOR THE CHEMICAL PROCESS INDUSTRY

Carbon fibre reinforced PVDF

XECARB® 45-C10

10% carbon fiber reinforced PVDF

XECARB® 45-C20

20% carbon fiber reinforced PVDF

Structurally modified carbon fibre reinforced PVDF

XECARB® 45-C10-S

10% carbon fiber reinforced PVDF

XECARB® 45-C20-S

20% carbon fiber reinforced PVDF

XENIA® SET TO UNVEIL NEW CERAMIC THERMOPLASTIC COMPOSITES AT EPHJ 2025

Xenia Materials announces the launch of XERAMIC™, an innovative range of ceramic thermoplastic compounds developed to deliver high performance combined with refined aesthetic appeal.

Thanks to its ceramic content, Xenia’s XERAMIC™ range offers high thermal conductivity, enabling efficient heat dissipation and a cold-touch surface, as well as high density, making it a distinctive addition to Xenia’s typically lightweight-focused portfolio.

Thermal Conductivity

Density

Hardness

XERAMIC™ materials are formulated by combining selected base polymers with a precisely engineered ceramic filler.

XERAMIC™ is now available on a bio-based PPA polymer matrix, in the PURE version charged with a high level of ceramic content, and in the CORE version, which combines carbon fibre with ceramic reinforcement.

THE MATERIALS

XERAMIC™ | PURE

High Percentage of Ceramic Content

XERAMIC™ | Pure is formulated using a bio-based PPA polymer matrix and a high content of engineered ceramic filler.

This combination delivers a unique balance of performance, thermal conductivity and aesthetic refinement, making it ideal for applications where surface quality and high properties are both essential.

XERAMIC™ | CORE

Ceramic Content and Carbon Fibre Reinforcement

XERAMIC™ | Core builds on Xenia’s expertise in fibre-reinforced composites by combining ceramic filler with carbon fibre reinforcement.

Based on a bio-sourced PPA polymer matrix, this innovative formulation merges the distinctive characteristics of ceramic reinforcement with the mechanical properties of carbon fibre.

With the launch of XERAMIC™, Xenia further consolidates its commitment to the development of advanced thermoplastic composites, combining exceptional mechanical performance with refined aesthetics to address the growing demand for solutions where both technical excellence and design value are essential.

CONDUCTIVE MATERIALS FOR THE CHEMICAL PROCESS INDUSTRY

In the Chemical Process Industry (CPI), selecting the right materials is essential to ensuring the longevity and reliability of critical components such as pumps, valves, pipes, cables, batteries and sensores.

Xenia has designed a new range of materials based on PVDF, engineered to combine high performance and reliability for advanced applications.

Compared to neutral PVDF, these compounds offer permanent electrical conductivity, ensuring stable antistatic performance over time (ATEX Compliance) while preserving PVDF’s exceptional chemical resistance. Their V0 fire resistance rating enhances safety, while improved UV resistance extends durability, even in demanding outdoor environments.

At the same time, their processability remains similar to pure PVDF, ensuring complete integration into existing manufacturing workflows.

Chemical Resistance

Electrically Conductive

Fire Resistance

UV Resistance

PVDF is a thermoplastic fluoropolymer that provides excellent chemical resistance, including high tolerance to strong acids and oxidizing agents.

It exhibits outstanding thermal stability, with an operating range of -40°C to 150°C, and is highly resistant to UV radiation, making it ideal for outdoor applications.

With remarkable mechanical strength, abrasion resistance and structural integrity even at high temperatures, PVDF also exhibits piezoelectric properties and chemical inertness, making it highly durable in demanding conditions.

THE MATERIALS

XECOND™ E 45

Easy Flow Conductive PVDF

XECOND™ E 45 is a high-performance conductive PVDF material designed for electrical conductivity applications.

It is easily processable and is suitable for both injection moulding and extrusion processes.

With a tensile modulus 20% higher than standard PVDF, XECOND™ E 45 offers enhanced strength and durability, making it ideal for use in demanding electrical applications where conductivity is essential.

XECARB® 45

Carbon Fibre Reinforced PVDF

Available with 10% or 20% of reinforcement, XECARB® 45 is Xenia’s advanced carbon fibre reinforced PVDF.

Designed for both structural and conductive applications, it expands the range of possibilities compared to standard PVDF.

With a volumetric resistivity of 10^-3 and high structural strength, XECARB® 45 is ideal for demanding applications that require enhanced mechanical properties and electrical conductivity.

XECARB® 45-S

Stracturally Modified Carbon Fibre Reinforced PVDF

XECARB® 45-S is a carbon fibre reinforced PVDF, based on structurally and chemically modified PVDF.

Available with 10% or 20% carbon fibre reinforcement, this high-end material is designed for advanced structural and conductive applications.

It combines exceptional resistance to chemically aggressive substances with superior structural integrity, delivering outstanding durability and strength for the most demanding environments.

Available also in filament form for 3D printing:

INDUSTRY & APPLICATIONS

HIGH-PERFORMING MATERIALS FOR EYEWEAR APPLICATIONS

In eyewear manufacturing, the careful selection of materials is critical to achieving an optimal balance between performance, comfort, style and sustainability.

Applications such as frames, protective eyewear, temples and other components require essential properties like lightweight, impact resistance and durability.

These characteristics are directly influenced by the choice of the right materials and are crucial to ensuring eyewear that is both durable and comfortable, enhancing the overall user experience.

Xenia’s expertise allows manufacturers to achieve high flexibility in terms of mechanical performances and design, resulting in versatile applications suitable for different environments.

Performances

Lightweight

Flexibility

Impact Resistance

Beyond aesthetics and design, performance-oriented materials are crucial for applications requiring precision, reliability and peak performance.

For the eyewear industry, Xenia has developed innovative materials that provide high-level solutions for the most demanding applications, from carbon fiber-reinforced composites to ultra-lightweight compounds.

XENIA SET TO UNVEIL NEW WHITENED SHADE MATERIALS AT JEC 2025

Xenia® Materials is pleased to introduce the Whitened Shade colour option to its carbon fibre reinforced grades. This new finish offers a lighter base colour compared to the natural black variant, making it colourable with masterbatch during the injection moulding and 3D Printing processes by pellets.

Carbon-fibre reinforced thermoplastics composites are highly valued for their strength, lightweight and durability, making them essential materials in sectors such as consumer goods, industrial applications and mobility. However, the natural black colour of carbon fibre, when combined with thermoplastic matrices, has traditionally limited its use in applications where design is important.

To overcome this challenge, Xenia has developed a new technology that produces carbon fibre reinforced materials with a whitened base colour. The result is a thermoplastic compound that not only offers excellent mechanical properties but also achieves a Whitened Shade colour, allowing it to be coloured by adding masterbatch during both the injection moulding and 3D printing processes by pellets.

Design

Performances

Lightweight

Colorability

Xenia will showcase its Whitened Shade materials at JEC World 2025, taking place from 4 to 6 March in Paris – France, at Hall 5, Booth D79.

XENIA MATERIALS COLLABORATES WITH POLITECNICO DI MILANO ON THE PRODUCTION OF A COMPETITIVE AIRCRAFT

Xenia® Materials is proud to have contributed to the success of Nyx, the innovative aircraft designed by Fly Mi – EUROAVIA Milano, the student association of engineers and designers from the Politecnico di Milano.

This project represents a significant achievement for both the Politecnico di Milano and Xenia Materials, highlighting how collaborations between industry and academic institutions can lead to groundbreaking advancements in innovation.

For the academic year 2023/2024, Fly Mi decided to participate in its first international competition: the Air Cargo Challenge, held in Germany last July.

Faced with the rules and restrictions imposed by the competition, the team developed and built Nyx, an ambitious drone crafted from composite materials. With a length of 1,5 meters and a wingspan of 3 meters, Nyx represents a remarkable achievement in engineering and design.

To meet the high demands of the Nyx project, Xenia Materials stepped in, supplying XECARB® 40-C20-3DP, a 20% carbon fibre reinforced polycarbonate specifically designed for Additive Manufacturing market. This material was essential in the creation of the moulds used for laminating the wings and control surfaces, which are crucial for the drone’s flight capabilities.

“With its low CTE values, the material provided by Xenia significantly reduced issues related to thermal shrinkage during the design phase, enabling us to produce higher-quality parts.

Furthermore, the absence of permanent deformations in the moulds after use, along with the resistance of internal surfaces to release agents, allowed us to repeatedly laminate the movable surfaces and test various internal configurations to find the best solution.” said the students who took part in the project.

The feedback of the engineers reflects how Xenia’s advanced material ensured the reliability and superior performance needed for the ambitious goal of the project:

“At Fly Mi EUROAVIA, we partnered with Xenia Materials to meet the demanding performance standards of our project. The lightness, recyclability and ease of handling of the moulds were key advantages, complemented by the increased sustainability of the process, adding significant value to our work.

Thanks to this collaboration, the Nyx project successfully achieved its ambitious goals, integrating advanced material science with pioneering aerospace engineering.” said M.H., serving as president of the Fly Mi Euroavia association at the time.

Discover more about the Academic & Research Support Program, Xenia’ s dedicated program for collaboration with universities, research centres and institutes of technology.

NEW RANGE OF MATERIALS MADE FROM 100% BIOBASED PA10.10

XECARB® 31 is Xenia’s latest addition to its Advanced Materials Collection.

This new carbon-fibre reinforced material, based on PA10.10, delivers exceptional strength and durability while being 100% bio-based.

This new material not only represents a step forward in performance but also aligns with Xenia’s commitment to sustainability.

With up to 50% carbon fibre reinforcement, XECARB® 31 ensures increased stiffness, making it ideal for structural applications that demand superior mechanical strength.

Furthermore, this new compound is well-suited for environments that require higher operating temperatures without compromising performance, thanks to its high melting point.

The PA10.10 base polymer ensures significantly reduced moisture absorption, improving long-term durability. Its excellent cold impact resistance makes it suitable for applications frequently exposed to low temperatures, such as outdoor environments and high-altitude settings.

The combination of lightweight construction and rigidity makes the XECARB® 31 optimal for high-performance sports equipment. This material enhances product durability without adding unnecessary weight, making it ideal for competitive sports where performance is crucial.

In the industrial sector, chemical resistance and mechanical stability are key advantages for parts exposed to harsh working conditions. This includes applications where the material’s ability to withstand heat, oil, and grease ensures longevity and reliable performance.

As a bio-based material sourced from castor oil, the PA10.10 significantly reduces dependence on fossil fuels, addressing the growing demand for eco-friendly solutions.

This new compound promotes a more circular and environmentally conscious approach to manufacturing, offering high performance without compromising on sustainability.

XECARB® 31 is available in the XERCARB®, XECARB® HM and XECARB® ST versions

100% Biobased

High Mechanical Properties

Chemical Resistance

Cold Impact Resistance